Does the powerful hum of your heavy machinery sound a bit different lately? Maybe there’s a new noise, a slight hesitation, or a smell that wasn’t there before. Your industrial engine is the core of your operation, and it often sends out quiet warnings before a major issue arises.

Ignoring these early signs can lead to unexpected and expensive breakdowns. This results in significant downtime that hurts your productivity and your bottom line. By learning to spot these warnings, you can opt for a smart solution and restore your engine’s performance.

1. Increased Fuel Consumption

You have a clear idea of how much fuel your equipment uses during a normal workday. If you find yourself at the fuel tank more often, it’s a strong indicator that something is wrong. An engine that suddenly becomes thirstier is working inefficiently and burning more fuel to get the same job done.

This drop in fuel economy is often caused by internal wear and tear. Components like piston rings and cylinder liners are designed to create a tight seal for compression. When they wear down, this seal weakens, causing the engine to lose power and waste fuel.

2. Strange Noises and Vibrations

An engine in good condition operates with a smooth and consistent sound. You should always pay attention to new or unusual noises coming from the engine bay. These sounds are direct messages from your engine telling you that a component is failing.

Specific sounds can point to different problems inside the engine. A deep knocking or banging noise often suggests worn-out crankshaft bearings. A high-pitched grinding or squealing sound can indicate issues with other moving parts that are making improper contact.

3. A Noticeable Loss of Power

Your machinery, which once handled heavy loads effortlessly, may now feel sluggish and weak. This reduction in power is one of the most direct symptoms of significant engine wear. The engine can no longer generate the force it was originally designed to produce.

This issue can stem from several key areas inside the engine. A thorough inspection is necessary to find the exact source of the problem. It usually involves examining the engine’s most critical internal parts.

The Problem with Worn Pistons

An engine’s pistons and rings are vital for creating the compression needed for combustion. When these parts wear out, hot gases can escape past them in a process called “blow-by.” Our specialized piston rod services can measure and restore these parts to exact factory standards.

Issues with the Cylinder Head

The cylinder head acts like the engine’s control center for air and fuel. If its seals or gaskets fail, or if valves are not closing properly, the engine loses compression and runs poorly. Professional cylinder head services ensure this complex component is perfectly sealed and working correctly.

Crankshaft and Camshaft Wear

The crankshaft and camshaft must work in perfect harmony to control the engine’s timing. If these parts become worn, this timing can be disrupted, leading to poor performance and even severe internal damage. Our expert crankshaft services restore the precision of these essential components.

4. Excessive or Colored Exhaust Smoke

The smoke coming from your engine’s exhaust pipe provides a clear look into its internal health. While a small amount of vapor can be normal, thick plumes of colored smoke signal a serious problem. Each color of smoke points to a specific type of internal failure.

Paying attention to the exhaust is an easy way to diagnose a potential issue. Here is a breakdown of what the different colors typically mean:

- Blue Smoke: This color means the engine is burning oil. Oil is leaking into the combustion chamber, likely past worn valve seals or piston rings, and can lead to fouled spark plugs and carbon buildup.

- Black Smoke: This indicates that the engine is receiving too much fuel and not enough air. This could be due to faulty fuel injectors, which our diesel injection services can accurately diagnose and repair.

- White Smoke: Thick, sweet-smelling white smoke is a major red flag that coolant is leaking into the engine’s cylinders. This is often caused by a cracked cylinder head or a blown head gasket and requires immediate attention to prevent hydrolocking the engine.

5. Frequent Overheating

Is your engine’s temperature gauge consistently running high? An engine that regularly overheats is in serious trouble. Excessive heat can cause metal parts to warp, expand, and seize, leading to catastrophic and often irreparable damage.

While the problem could be as simple as a faulty thermostat, it often points to deeper internal issues that require professional inspection. An overheating engine is a symptom of a larger problem. These problems can include:

- A blown head gasket that allows hot exhaust gases to enter the cooling system.

- Increased internal friction from worn parts that are no longer properly lubricated.

- A crack in the cylinder block that compromises the cooling channels.

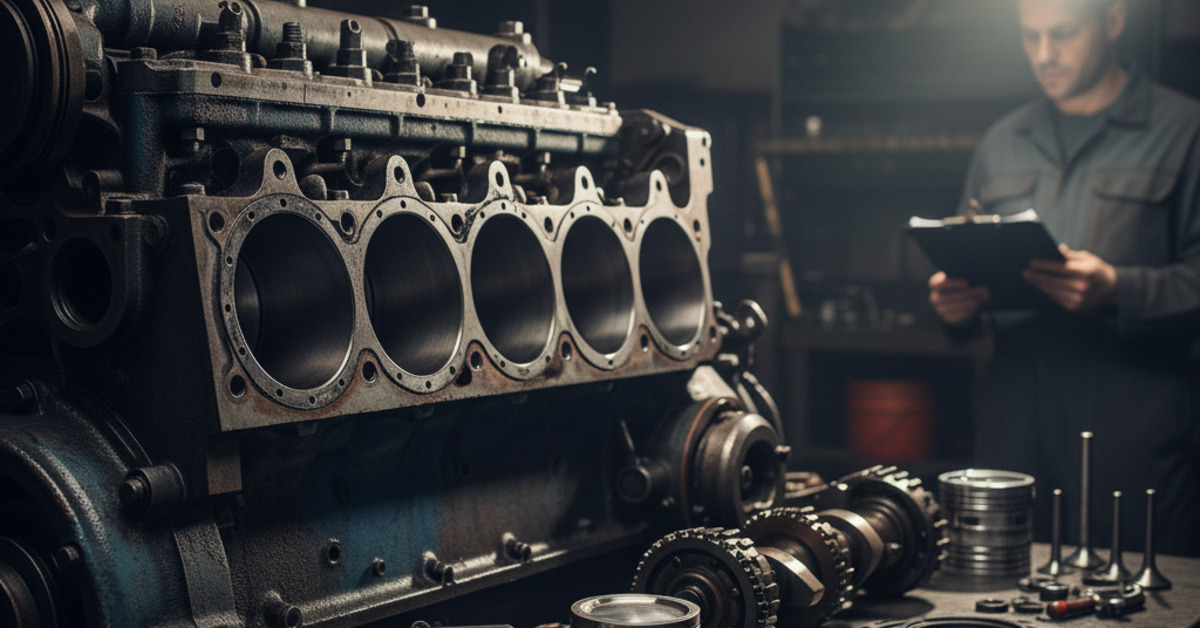

What is Industrial Engine Reconditioning?

Engine reconditioning is a detailed process that brings a worn engine back to factory specifications. It is a cost-effective and sustainable alternative to a full engine replacement. The process involves completely disassembling the engine and putting every single component through a rigorous inspection.

Once disassembled, all parts are chemically cleaned to remove carbon, oil, and grime. Our technicians then use precise measuring tools to check for wear and damage. Any component that does not meet the original manufacturer’s standards is either expertly repaired or replaced, ensuring the engine performs like new.

Conclusion: Act Before It’s Too Late

These five signs—high fuel use, strange noises, power loss, colored smoke, and overheating—are clear indicators that your engine needs help. They are not minor issues that will resolve themselves over time. Addressing them early with professional help is the best way to avoid a complete and costly failure.

At Merdeka Precision, we see reconditioning as a craft that combines engineering skill with precision technology. Our expert team uses advanced methods to restore your engine’s power and reliability. If your engine is showing any of these signs, contact us today to learn how our engine reconditioning services can benefit your operation.

Have you experienced any of these engine problems in your machinery? Share your story in the comments below.