Have you ever had an engine that mysteriously overheats or just does not have the power it used to? Your first thought might be a problem deep in the engine block, but the issue often lies right on top. The cylinder head is one of the most complex and critical parts of your engine, and it can fail in many different ways.

When people hear about cylinder head problems, they almost always think of a single issue: a crack. While a cracked head is a serious failure, it is far from the only thing that can go wrong. This guide will look at seven common problems that can cause a major headache, even if the head is not cracked.

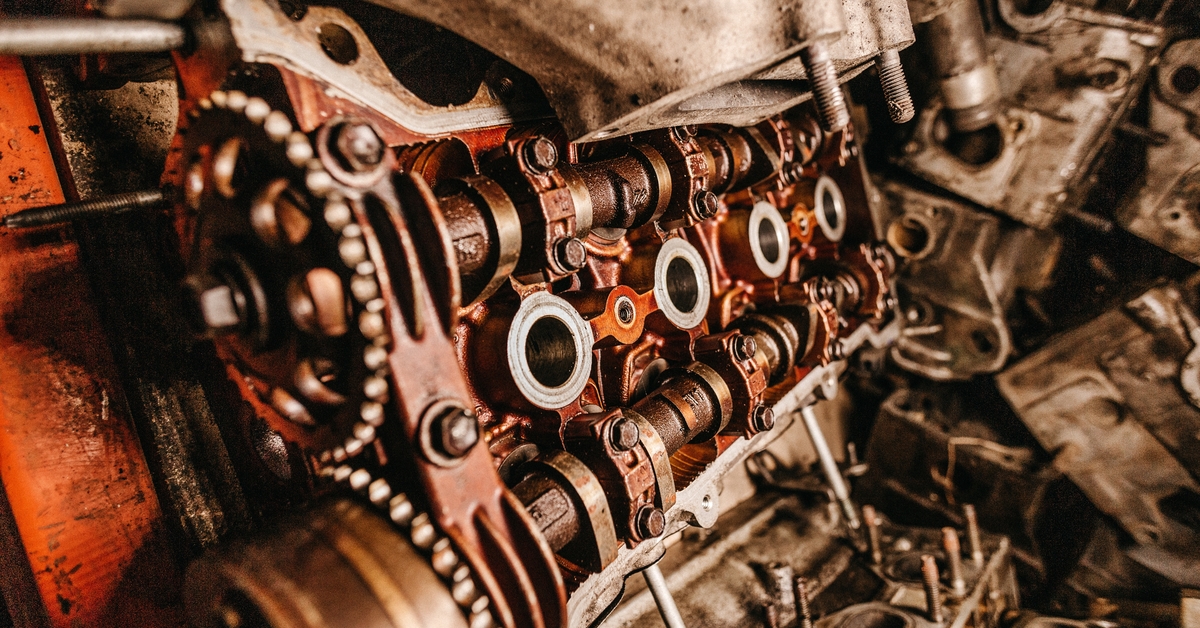

1. Warped Cylinder Head Surface

A cylinder head must be perfectly flat where it meets the engine block. A “warped” head is one that has become bent or twisted, usually from extreme overheating. Even a tiny bend, smaller than the thickness of a piece of paper, can ruin the seal.

When the head is not flat, the head gasket cannot seal correctly. This allows hot gases, coolant, and oil to leak between the head and the block. This is the most common reason for a “blown” head gasket, and it must be fixed by resurfacing the head.

2. Worn or Damaged Valve Guides

Every valve in your engine has a long stem that slides up and down. The valve guide is a small tube that supports this stem and keeps it moving in a perfectly straight line. These guides are a high-wear item.

Over thousands of hours, the guides can wear into an oval shape, making the valve loose. The most common symptom is a puff of blue smoke from the exhaust when you first start the engine. This is caused by oil leaking down the loose guide and into the combustion chamber.

3. Burnt or Leaking Valves

The valves must create a perfect, gas-tight seal when they close. A “burnt valve” is a valve that has overheated, causing a small piece of its edge to chip or burn away. This creates a tiny gap that allows hot combustion gases to escape when they should be pushing the piston down.

A burnt valve will cause a major loss of power and a very rough, shaky idle. The engine will have a “dead miss” because one cylinder is no longer able to produce any power. This problem requires a valve job to fix.

4. Worn Valve Seats

The valve seat is the hard metal ring in the cylinder head that the valve seals against. Every time the valve slams shut, it causes a tiny amount of wear on this seat. Over a long service life, the valve and seat wear down together.

As the seat wears, the valve sinks deeper into the cylinder head. This gradual wear will cause a slow loss of compression and make the engine feel weak. This is a very common issue that is addressed during a professional engine reconditioning.

5. Problems with the Camshaft (A Deeper Look)

In many modern engines, the camshaft is located inside the cylinder head. This part is responsible for opening and closing all the valves at the correct time. When diagnosing cylinder head problems, people often overlook the camshaft and its related parts.

Worn Camshaft Lobes

The lobes are the egg-shaped bumps on the camshaft that push the valves open. The tips of these lobes can wear down over time, becoming rounded. When this happens, the lobe cannot push the valve open as far as it should.

This starves the engine of air and fuel, leading to a significant loss of power. A worn lobe will often produce a rhythmic “ticking” sound from the top of the engine. Professional camshaft services can measure and repair this type of wear.

Damaged Camshaft Bearings

The camshaft does not spin on ball bearings. It spins on smooth, polished surfaces in the head called bearings or journals. These surfaces ride on a thin film of high-pressure oil.

If the engine is ever run low on oil, these bearings are often the first things to be damaged. The metal surfaces will rub together, creating deep scratches and grooves. This failure will produce a deep knocking or grinding noise from the upper part of the engine.

Failed Camshaft Seals

At the end of the camshaft, a simple rubber seal stops oil from leaking out of the engine. Over time, heat and age can cause this seal to become hard, brittle, and cracked.

This is a very simple part, but its failure can make a big mess. The most obvious symptom is an oil leak dripping from the side of the engine, right behind the main pulley.

6. Blocked Coolant or Oil Passages

A cylinder head is not a solid piece of metal. It is filled with a complex maze of tunnels and passages. These passages allow coolant and oil to flow through the head, carrying away heat and providing lubrication.

If you use the wrong type of coolant or neglect your oil changes, sludge and scale can build up. This buildup can create a clog, just like in the pipes of a house. A clog will create a “hot spot” in the head, which can quickly lead to warping or a crack.

7. Blown Head Gasket (The Main Symptom)

The head gasket is not technically part of the cylinder head. However, its failure is the number one symptom that points to a deeper cylinder head issue. The gasket is the “weak link” that fails because the head has warped or has a damaged surface.

A blown head gasket is one of the most serious cylinder head problems. It can cause a long list of symptoms as fluids are forced into places they should not be.

Common signs of a blown head gasket include:

- Thick, sweet-smelling white smoke from the exhaust (burning coolant).

- A milky, frothy, or “chocolate-milk” look to your engine oil.

- Bubbles or foam appearing in your radiator.

- Constant engine overheating, even on cool days.

- A loss of coolant with no visible external leak.

How Professionals Diagnose These Problems

A good mechanic does not guess what the problem is. They use a specific set of tests to confirm the issue before they ever remove a single bolt. This diagnostic process is key to an accurate repair.

Here is a common list of diagnostic steps:

- Compression Test: This test measures how much pressure each cylinder can build. A low reading on one cylinder points to a leaking valve or bad piston ring.

- Cylinder Leak-Down Test: This test pumps compressed air into the cylinder. The mechanic then listens for where the air is escaping. Air hissing from the exhaust points to a bad exhaust valve.

- Cooling System Pressure Test: This tool puts pressure on the cooling system. If the pressure gauge drops, it confirms there is a leak, even if you cannot see it.

- Visual Inspection: Once the head is off, a technician will check for obvious damage. They will use a precision straight edge to check the head surface for any warping.

- Pressure Testing the Head: The head itself can be tested for hidden cracks. It is sealed off and pressurized with air while being held underwater. Any bubbles will reveal the exact location of a tiny crack.

Conclusion: A Complex but Repairable Component

The cylinder head is one of the most critical and complex parts of your engine. While a crack is a major failure, it is not the only issue. Worn valves, bad guides, warped surfaces, and camshaft problems can all cause major engine trouble.

Proper maintenance, especially keeping your cooling system clean and your oil level full, is the best way to prevent most of these issues. A little prevention can save you from a very expensive repair.

What is the most unusual engine problem you have ever had to fix?

At Merdeka Precision, we are experts in diagnosing and repairing all types of cylinder head issues. Our professional cylinder head services are a key part of our complete engine reconditioning solutions. We serve a wide range of industries that depend on reliable machinery. If your engine is showing signs of trouble, contact us today to learn how our team and our services can help.