Imagine throwing away an entire house just because the roof has a few leaks. You would likely call that a waste of money and resources. Many businesses do the same thing when they scrap a large engine instead of fixing it.

Industrial engines are the expensive heart of your heavy equipment. You can choose to buy a new one or restore what you already own. This guide helps you see the true value by looking at the roi of industrial engine reconditioning.

Understanding the ROI of Industrial Engine Reconditioning

The cost to buy a brand-new industrial engine is often very high. You must pay for the metal, the factory labor, and the global shipping fees. These prices continue to rise every year due to material shortages.

Restoration usually costs only a fraction of a new purchase. In roi of industrial engine reconditioning, you pay for skilled labor and a few new parts like bearings or seals. This lower starting price is the first step in seeing a high return.

Calculating Direct Cost Savings

You save money immediately when you do not buy a new engine block. The iron and steel in your current engine are still strong and useful. You simply replace the small parts that actually wear out over time.

Your savings can reach fifty percent or more compared to a new unit in roi of industrial engine reconditioning. This extra cash stays in your bank account for other important projects. Lower costs at the start make your final profit much larger.

The Formula for Your Return

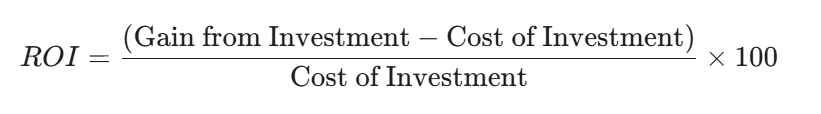

You can use a simple math formula to find your success rate. This helps you explain the choice to your board or your manager. A clear number proves that you are making a smart business move.

The formula for return on investment is:

A high percentage means you are using your company money very well. Most operators find that reconditioning offers a better ratio than buying new.

Performance and Efficiency Gains

Worn engines waste a lot of fuel because they lose their internal seal. This loss of pressure means the engine must work harder to do the same job. You pay more for diesel every day when your engine is tired.

Restoration brings back the tight seal between the pistons and the walls for your roi of industrial engine reconditioning. Your fuel costs will drop as soon as the machine returns to the field. This daily saving adds up to a large sum over a single year.

The Technical Foundation of Your Investment

We look at the core parts of the machine to ensure the best results. Each part must meet exact factory rules to work correctly. This technical care is why a restored engine lasts so long.

Restoring the Cylinder Block

The block is the heavy foundation that holds everything together. Our cylinder block services ensure this base is straight and strong. We hone the walls to make sure the new rings can seal the power inside.

Polishing the Crankshaft

The crankshaft turns the force of the fire into a spinning motion. We use expert crankshaft services to remove any small scratches or rough spots. A mirror finish on this part reduces friction and stops the engine from getting too hot.

Fixing the Cylinder Head

The head controls how the air and fuel enter the engine cylinders. Our cylinder head services stop any leaks from the top. A flat and clean head is the only way to prevent a blown gasket.

Balancing the Piston Rods

The rods connect the pistons to the spinning shaft at the bottom. We use piston rod services to make sure every rod is the same weight and shape. Balanced parts make the engine run smooth and stop it from shaking itself apart.

Calibrating the Fuel System

Modern engines need a perfect mist of fuel to run cleanly. Our diesel injection services ensure your injectors spray exactly the right amount. This work stops the black smoke and saves you even more on your fuel bill.

Reducing Operational Downtime

Waiting for a new engine to arrive can take many months today. Global shipping is slow and many factories have a long backorder list. Your machine makes zero money while it sits empty and quiet in the yard.

A local shop can often finish a restoration in just a few weeks. You get your machine back to the job site much faster than waiting for a delivery. Getting back to work sooner is a huge part of your total return.

Avoiding Hidden Replacement Costs

A new engine often needs new mounts, wires, or cooling hoses to fit. These small parts add a lot of extra cost that you might not see at first. You also have to pay your team to learn how to fix a new model.

Restoring your old engine means it fits perfectly back into the same space. All your current spare parts in the warehouse will still work with the machine. Hence like this roi of industrial engine reconditioning, you avoid the “surprise” costs that always come with a brand-new piece of technology.

Extending Asset Life Cycles

Heavy machinery is a major asset on your company balance sheet. When you restore the engine, you add many years to the life of that asset. This delays the need to spend millions on a new fleet of machines.

Your equipment stays productive for a longer period of time. This spreads the initial cost of the machine over a wider window. Your profit per hour increases as the machine gets older but stays reliable.

Environmental Sustainability Credits

Building a new engine requires a lot of mining and smelting of iron. You help the planet by recycling the hundreds of pounds of metal already in your machine. This choice reduces the carbon footprint of your entire operation.

Many customers now look for green partners when they hire a contractor. You can use your restoration program as proof of your care for the earth. This can help you win new contracts and grow your business reputation.

The Importance of Precision Engineering

We use high-tech machines to make sure every part is perfect. This is not a simple repair; it is a full industrial process. Quality work of roi of industrial engine reconditioning is the only way to ensure your investment pays off.

Our precision component manufacturing ensures that every small piece meets the highest standards. We also use expert fabrication to fix any damage to the engine housing. Accurate work prevents the failures that can ruin your profit.

Impact on Resale Value

A machine with a worn engine is very hard to sell for a good price. Buyers see it as a risk and will offer you very little money for it. They know they will have to spend a lot to fix it themselves.

A machine with a newly restored engine is a very valuable asset. You can show the buyer the test results and the warranty papers. This allows you to ask for a much higher price when you decide to sell.

Managing Your Risk

A sudden engine break can stop your most important project. You might face fines for being late or lose the trust of a big client. Restoring your engine is a way to stop these risks of roi of industrial engine reconditioning before they happen.

You choose when to do the work instead of waiting for a break. This allows you to plan your schedule during a quiet time of the year. Being in control of your machine is a vital part of your business success.

Training and Mechanic Familiarity

Your mechanics already know how to work on the engines you own. They have the tools and the knowledge to do a great job every day. A new engine often requires expensive new software and training for your team.

You save a lot of time and money by staying with a familiar design. Your team stays confident and can fix small issues much faster. This internal knowledge is a valuable resource for your company.

Tax and Accounting Benefits

Repairs are often treated differently than new purchases in your taxes. You can often write off the cost of a restoration much faster than a new machine. Talk to your accountant to see how this helps your specific situation.

A faster write-off means you keep more of your cash right now. This improved cash flow allows you to grow your business or pay off debts. It is another way that restoration helps your financial health.

Why Quality Standards Matter

We follow strict ISO rules to make sure our work is the best. Every measurement is checked twice before the engine is put back together. This level of care is what makes our engine reconditioning work so reliable.

A clean workspace stops dirt from getting into your new bearings. We treat every engine like it is going into a brand-new machine. This focus on quality is how we protect your money and your fleet.

Summary of ROI Factors

You gain value from many different areas when you choose to restore. It is a smart choice that helps your wallet, your machines, and the planet. Here is a list of the ways you win:

- Initial costs are much lower than a new engine purchase.

- Fuel economy improves, saving you money on every shift.

- The machine returns to work much faster, reducing lost income.

- You avoid the costs of training and new spare parts.

- Resale value goes up, making your asset worth more.

Final Thought on Business Value

Calculating the roi of industrial engine reconditioning shows that it is a wise choice. You keep your reliable equipment moving while spending less of your hard-earned cash. It is a balanced way to manage your heavy machinery for the long term.

Quality restoration gives you a machine you can trust for many years. You gain all the power of a new unit without the high price or the long wait. It is the best way to keep your business running strong.

Do you have an engine in your fleet that is starting to show its age?

At Merdeka Precision, we know that your business depends on strong and reliable machines. We provide high-quality precision engineering Tangerang to help companies reach their best results. Our team uses the latest tools and years of experience to restore engines for many different fields. We are ready to help you with our full range of manufacturing and repair solutions. Would you like us to help you evaluate your engine’s current health?