What do you do when your most expensive piece of machinery starts to fail? The engine is losing power, making strange noises, and you know a big bill is coming. You might think you have only one choice: buy a brand new, very expensive replacement engine.

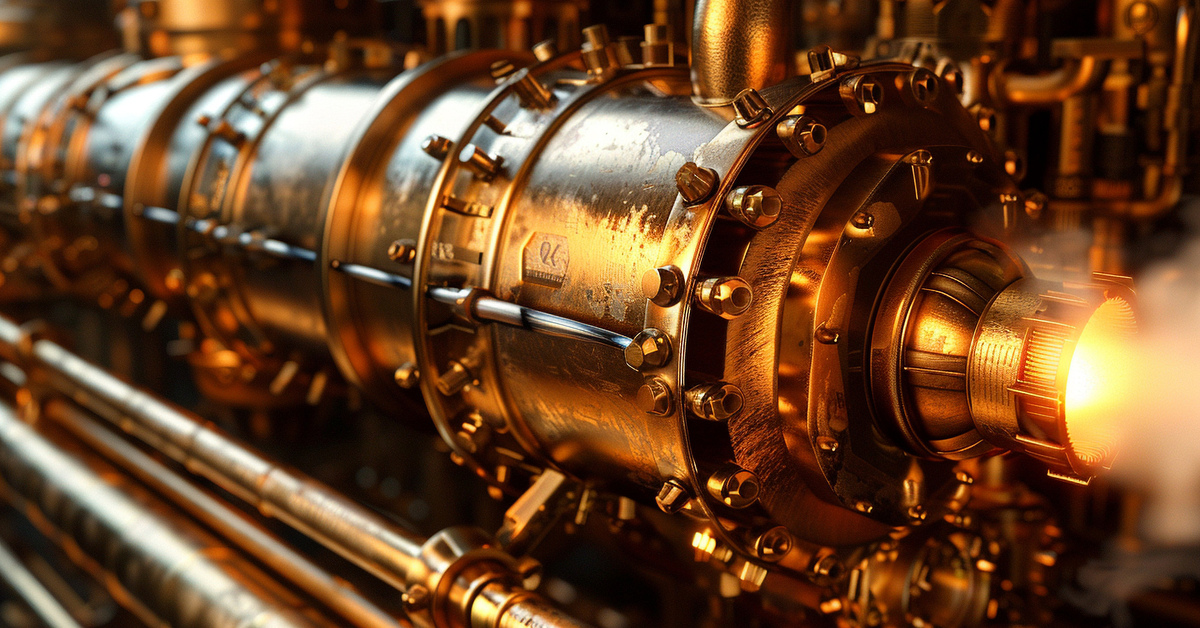

But there is another, smarter option that can save you time, money, and stress. This is the choice of engine reconditioning. It is a process that restores your old engine to a like-new condition. Let’s look at the top 10 benefits of industrial engine reconditioning.

1. A Major Reduction in Cost

The most important industrial engine reconditioning benefit for any business is the cost. A new replacement engine from the original manufacturer is extremely expensive. Reconditioning your existing engine costs just a fraction of that price.

You get the same performance and reliability as a new engine without the high price tag. This allows you to put that saved money back into other important parts of your business. It is a smart financial decision that improves your bottom line.

2. Restored Engine Performance and Power

Over thousands of hours, an engine’s internal parts wear out, and it loses its original power. It might struggle with heavy loads that it used to handle with ease. Reconditioning fixes all the internal wear that causes this performance loss.

The process restores the engine’s core components to their original factory specifications. This means your machine will run just like it did when it was new. You get all of its power and capability back, allowing your team to work productively.

3. Improved Fuel Efficiency

A worn engine wastes a lot of fuel. When pistons and cylinders wear down, the engine loses compression. This means fuel is not burned completely, and a lot of it goes out the exhaust as unburnt smoke.

Reconditioning fixes these compression issues completely. A properly serviced cylinder block and new piston rings restore that seal. This ensures every drop of fuel is used for power, which lowers your daily operating costs.

4. Extends the Life of Your Machinery

Your heavy machinery is a huge financial investment. When the engine fails, the entire machine becomes useless. A new engine might be so costly that it forces you to consider scrapping the whole machine.

Reconditioning gives your equipment a new lease on life. It adds many more years of productive service to your valuable asset. This helps you get the most from your initial investment and delays the need for new capital spending.

5. Increased Reliability and Less Downtime

An old, worn engine is unpredictable. It can break down at any time, often in the middle of a critical job. This unplanned downtime costs your business money, delays projects, and hurts your reputation.

A reconditioned engine is completely reliable. It has been fully disassembled, inspected, and all wearable parts are replaced. You can trust it to start and run every day, just like a new engine, giving you peace of mind.

6. A More Sustainable and “Green” Choice

Manufacturing a new engine block and head uses a huge amount of energy and raw materials. When you buy a new engine, the old one is often just melted down as scrap. This creates a large environmental footprint.

Reconditioning is a form of industrial recycling. It reuses the main, high-energy components of the engine. This saves raw materials, reduces waste, and prevents a large amount of carbon from entering the atmosphere.

7. Faster Turnaround Time

Ordering a new industrial engine can sometimes take months, especially for specialized models. Supply chain delays are common. All the while, your expensive machine is sitting idle and not making you money.

A professional reconditioning service can often be completed much faster. You get your own engine back in a matter of weeks, not months. This gets your equipment back on the job and earning income sooner.

8. A Thorough Process You Can Trust

A reconditioned engine is not just a “repaired” engine. It is a detailed technical process where every part is measured and restored to precise standards. This guarantees the quality of the final product. The process is very thorough and involves several key stages.

Inspecting the Crankshaft

The crankshaft is the backbone of the engine. It is removed and checked for any microscopic cracks. Technicians then use a special grinding machine to restore its journals to a perfectly smooth and round surface. This ensures the new bearings will last for thousands of hours.

Restoring the Cylinder Head

The cylinder head controls the engine’s breathing and compression. It is resurfaced to be perfectly flat, which ensures a tight seal with the new head gasket. The valves and valve seats are also re-cut or replaced to prevent any compression leaks.

Servicing Piston Rods

The piston rods are carefully inspected for any bends or twists. The big end of the rod, where it connects to the crankshaft, is resized to be perfectly round. This is a critical step for new bearing installation and long-term reliability.

9. Comes with a Warranty

If you try to do a simple, in-frame “rebuild,” you usually get no guarantee. If the engine fails again a month later, you are responsible for the cost. This is a big financial risk for any business to take.

A professionally reconditioned engine from a reputable shop almost always comes with a warranty. This gives you confidence and peace of mind. You know that the work is backed by the company that performed the service.

10. Increases Your Equipment’s Asset Value

A piece of heavy machinery with a worn-out engine has a very low resale value. It is seen as a liability, not an asset. Selling it would mean taking a huge financial loss on your books.

An engine that has been professionally reconditioned adds significant value back to the machine. You can show buyers a receipt and warranty proving the heart of the machine is “like new.” This makes it a much more valuable asset if you ever decide to sell or trade it.

Conclusion: A Smart Investment

As you can see, the industrial engine reconditioning benefit list is long and valuable. It is a smart choice that saves money, restores performance, and increases reliability. It is also a faster and more sustainable option than buying a brand-new engine.

When your industrial engine starts to show its age, do not assume you need a complete replacement. A high-quality reconditioning can give you a “like-new” engine for a “like-used” price. This makes it one of the best investments you can make for your business.

What has been your biggest challenge when dealing with a failing industrial engine?

At Merdeka Precision, we see the power of reconditioning every day. Our expert technicians use precision equipment to bring old engines back to life. We provide a full range of engine reconditioning services for many different industries.

We are committed to providing reliable solutions that save our customers time and money. If you want to learn more about our services, please contact us for a consultation.