Is your heavy industrial engine losing power, making strange noises, or burning too much oil? When the heart of your machinery starts to fail, you might think your only option is a costly and time-consuming replacement. There is, however, a reliable and cost-effective alternative that can restore your engine to its original performance.

This process is known as engine reconditioning. It is a detailed procedure that involves completely disassembling a worn engine and restoring its core components to precise factory specifications. It is a solution that gives a tired engine a complete new lease on life.

Reconditioning vs. Rebuilding vs. Remanufacturing

People often use terms like “rebuilt,” “remanufactured,” and “reconditioned” as if they mean the same thing. In the engineering world, however, they have very specific meanings. Understanding this difference is key to knowing what you are paying for.

A “rebuilt” engine usually involves fixing only the specific parts that have failed. For example, if a piston breaks, a rebuild might replace that one piston and any related damage. It is a targeted repair, not a complete overhaul.

A “remanufactured” engine is one that is rebuilt in a factory setting to original specifications. The process is standardized, and the final product is often sold as a complete, ready-to-install unit. It is a high-quality option but can be expensive and may not use your original engine.

“Reconditioning” is the most detailed and transparent process of the three. It involves a specialist machine shop taking your specific engine, completely disassembling it, and restoring all its core components. You get your original engine back, but in a “like-new” state.

Signs Your Engine Needs Reconditioning

An engine will almost always give you warning signs before a major failure. These symptoms indicate significant internal wear that simple repairs cannot fix. Ignoring them can lead to a complete breakdown and damage the engine beyond repair.

Look out for these common red flags:

- Excessive blue or white smoke from the exhaust.

- A noticeable and consistent loss of power or pulling strength.

- A deep, rhythmic knocking or tapping sound from the engine.

- Using significantly more oil or fuel than usual.

- Constant overheating issues.

- Finding metal shavings in the engine oil during a change.

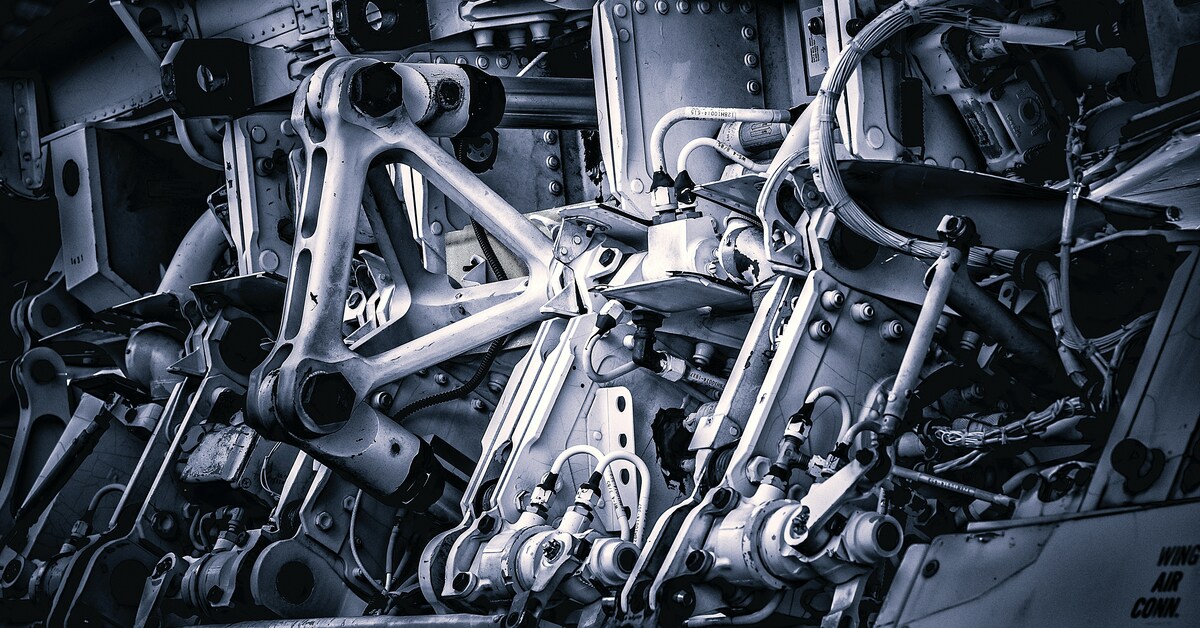

The Reconditioning Process: A Detailed Look

So, what is engine reconditioning when it comes to the actual work? It is a systematic, four-stage process that brings the engine’s core components back to a “like-new” state. This goes far beyond a simple repair and requires specialized machinery and expert technicians.

Step 1: Disassembly and Thorough Cleaning

The process begins by completely taking the engine apart. Every component, down to the last nut and bolt, is removed, organized, and tagged. The main block, head, and crankshaft are separated for individual treatment.

These core parts are then cleaned in industrial-grade systems, such as hot chemical baths or thermal ovens. This process strips away all the baked-on carbon, oil sludge, and grime. This cleaning is essential, as a technician cannot properly inspect a part that is still dirty.

Step 2: Detailed Inspection and Measurement

With all parts clean, a machinist performs a meticulous inspection. They use visual checks and high-precision tools like micrometers, calipers, and dial bore gauges. They measure key surfaces to determine the exact amount of wear, often down to a thousandth of an inch.

Technicians also use non-destructive testing, such as magnetic particle inspection (magnafluxing). This process can reveal tiny, microscopic cracks in components like the crankshaft or cylinder head. These cracks are invisible to the naked eye but would cause a catastrophic failure if not found.

Step 3: Precision Machining and Component Restoration

This stage is the true heart of the reconditioning process. Instead of just replacing the engine block, technicians restore it using cylinder block services. The cylinders are honed or bored to create a new, perfectly round surface for the piston rings.

The cylinder head is resurfaced to be perfectly flat, ensuring a tight seal with the head gasket. The valve seats and guides are also machined. Other key components like the camshaft are inspected, polished, or repaired to restore proper valve timing.

Step 4: Reassembly and Quality Control

Once all machine work is complete, the engine is carefully put back together in a clean environment. All wearable items are replaced with new, high-quality parts. This includes new pistons, piston rings, bearings, gaskets, and seals.

Technicians follow the manufacturer’s exact procedures and torque specifications. Often, the reassembled engine is tested. This can include spin testing to check oil pressure or even running the engine on a test stand to ensure it performs perfectly before it leaves the shop.

Core Components That Are Reconditioned

Reconditioning focuses on the main, high-value components of the engine. These are the parts that are too expensive to simply throw away. The goal is to restore their original geometry and surface finish.

Here are the most common parts that are serviced:

- Cylinder Block: This is the engine’s foundation. It is machined to ensure the cylinder bores are straight, round, and have the correct surface finish for the new piston rings.

- Cylinder Head: The head is resurfaced flat to prevent gasket leaks. Valve seats are recut to ensure valves close tightly and hold compression, which is vital for power.

- Crankshaft: This part converts the piston’s power into rotation. Worn journals are repaired through specialized crankshaft services, which involve grinding and polishing the surface for new bearings.

- Connecting Rods: These rods link the pistons to the crankshaft. They are checked for straightness, and the “big end” is resized to ensure it is perfectly round, a key step in professional piston rod services.

The Main Benefits of Engine Reconditioning

Choosing to recondition an engine is a major decision, but it offers significant advantages. It is a smart choice for businesses that rely on heavy machinery. It provides benefits over both buying new and simple, targeted repairs.

Here are the top benefits:

- Significant Cost Savings: A reconditioned engine is almost always significantly cheaper than a brand-new engine from the original equipment manufacturer (OEM). You get “like-new” performance for a fraction of the price.

- Environmental Sustainability: Reconditioning is an excellent form of industrial recycling. It reuses the massive, energy-intensive cast components like the block and head. This saves tons of raw materials and reduces the carbon footprint associated with new manufacturing.

- Guaranteed Quality and Reliability: Unlike a simple “rebuild,” a full reconditioning process addresses all potential wear points. Because every component is measured and restored to factory specifications, the resulting engine can be just as reliable as a new one.

- Faster Turnaround: In many cases, especially for specialized industrial engines, reconditioning your existing unit can be much faster. You avoid the long wait times that can come with ordering a new replacement engine from the manufacturer.

Conclusion: A Smart Choice for Worn Engines

So, what is engine reconditioning? It is a complete, top-to-bottom process that restores a worn engine’s core components to their original specifications. It is far more than a simple repair; it is a full renewal of the engine’s heart.

By addressing wear at its source, reconditioning gives old machinery a new lease on life. It is a reliable, economical, and sustainable alternative to a costly replacement. Before you scrap a tired engine, you should always consider the value of reconditioning.

Has your business ever had to choose between reconditioning an engine or buying a new one? What was your experience?

At Merdeka Precision, we specialize in bringing industrial engines back to peak performance. Our expert engine reconditioning services cover everything from precision machine work to full assembly for a wide range of industries. We understand the cost of downtime, which is why we are committed to delivering reliable and high-quality services. If your equipment is losing power, contact us to see how we can restore it.