Have you ever wondered how a large diesel engine produces so much power and torque? It is not just about the size of the engine. The real secret lies in how it delivers its fuel. It is one of the most precise and high-pressure systems in the world of machinery.

Unlike a gasoline engine that uses a spark plug, a diesel engine ignites fuel using only high pressure and heat. This process requires the fuel to be delivered in a very special way. This is the job of the diesel fuel injector systems, and this guide will explain how they work.

What is a Diesel Fuel Injector System?

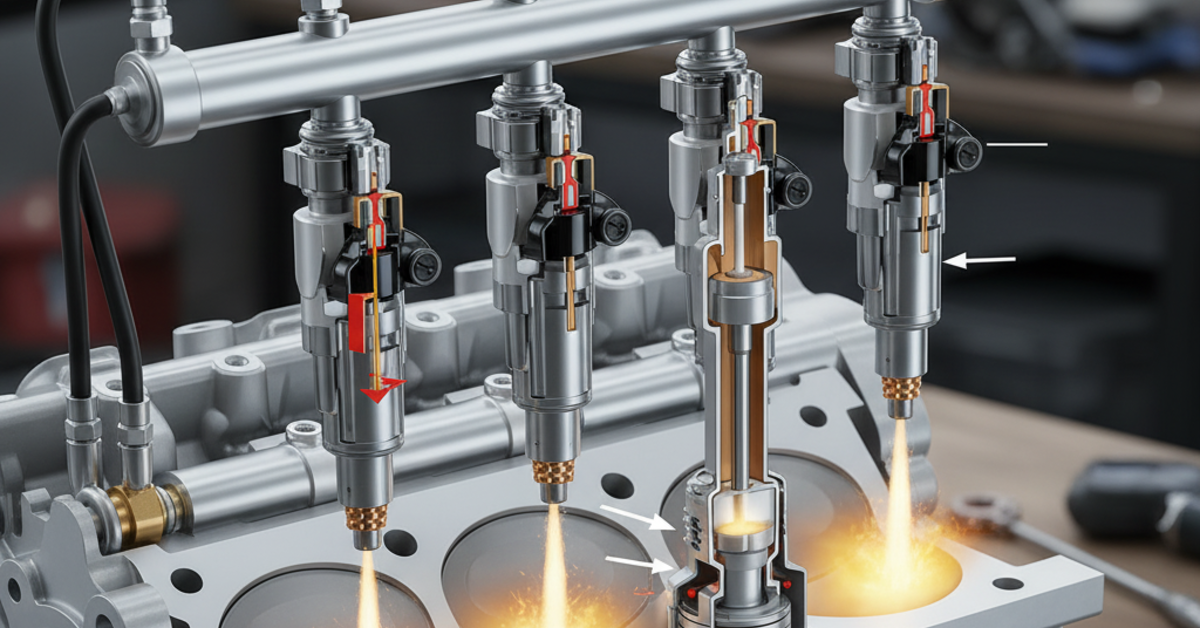

The main job of this system is to spray a very fine, atomized mist of diesel fuel directly into the engine’s cylinder. This must happen at the exact right millisecond and at an incredibly high pressure.

Think of it like a perfume bottle, but one that can spray with the force of 30,000 pounds per square inch (PSI). This extreme pressure is needed to turn the liquid fuel into a vapor that can ignite instantly in the hot, compressed air of the cylinder.

Why the Fuel Must Be a “Fine Mist”

This process is called “atomization,” and it is the key to a diesel’s power and efficiency. If you tried to light a log with a match, it would take a long time to burn. If you took that same log and turned it into fine sawdust, it would ignite instantly in a single flash.

The fuel injector does the same thing to diesel fuel. A few large drops would burn slowly, waste fuel, and create a lot of black smoke. A fine, fog-like mist mixes with the air and burns completely and very quickly, creating a powerful, clean combustion event.

The Main Components of the System

All diesel fuel injector systems use the same basic set of parts to move fuel from the tank to the engine. Each part has a very specific job to do.

Here are the key components of a typical system:

- Fuel Tank: This is where the diesel fuel is stored.

- Lift Pump: This is a low-pressure pump, often electric, that pulls fuel from the tank and pushes it toward the engine.

- Fuel Filter(s): These are the most critical parts for protecting the system. They remove tiny particles of dirt and any water from the fuel.

- High-Pressure Pump: This is the heart of the system. It takes the low-pressure fuel and compresses it to thousands of PSI.

- Fuel Lines: These special, thick-walled steel tubes carry the high-pressure fuel to the injectors.

- Injectors: These are the nozzles that spray the fuel into the engine’s cylinders.

A Closer Look at the Main Types of Systems

As engines have become more advanced, the fuel systems have also changed. The main goal has always been to get more precise control over the fuel injection. There are three main types you will find in industrial machinery.

H3: Mechanical Injection Systems

This is the classic, old-school system known for its rugged reliability. In this setup, a mechanical injection pump is driven by the engine’s gears. It is a very complex piece of machinery that does two jobs at once.

It creates the high pressure, and it also times the delivery, sending a pulse of high-pressure fuel to each injector at the right moment. It is simple, tough, and has no electronics, but it is not very precise.

H3: Electronic Unit Injector (EUI) Systems

This was a major step forward. In an EUI system, the high-pressure pump and the injector are combined into a single unit. There is one of these “unit injectors” for every cylinder.

The engine’s camshaft provides the force to create the pressure, but the engine’s computer (ECU) controls a solenoid on the injector. This gives the computer full control over when the fuel is injected, which improves efficiency and power.

H3: Common Rail Diesel Fuel Injector Systems

This is the modern standard used in almost all new diesel engines. It is the most precise and flexible system ever designed.

In a common rail system, a very powerful high-pressure pump fills a single tube, or “rail,” with fuel at extreme pressure (often over 30,000 PSI). This rail acts as a storage tank, holding the fuel at a constant high pressure. The injectors are connected to this rail, and they are sophisticated electronic valves.

The engine’s computer can then open each injector at any time and for any duration. It can even perform multiple injections per combustion cycle. This allows for a tiny “pilot” injection to quiet the engine, followed by the main “power” injection, and even a “post” injection to help clean the exhaust filter.

Common Problems and How to Spot Them

Diesel fuel injector systems are built with microscopic tolerances. The parts inside an injector are so precise that they must be measured in microns (millionths of a meter). Because of this, they are very sensitive to contamination.

Most injector problems are not from the part itself wearing out but from dirty fuel, water, or poor maintenance. Here are the most common problems you will see:

- Clogged Injector Nozzles: This is the most common issue. Tiny bits of dirt or carbon buildup from combustion can plug the microscopic holes in the nozzle tip. This ruins the spray pattern and causes black smoke, rough running, and low power.

- Leaking or Worn Injector: The valve (or “needle”) inside the injector can wear down, usually from water in the fuel causing rust. This allows fuel to drip into the cylinder when it should be closed. This makes the engine hard to start, wastes fuel, and can wash oil off the cylinder walls.

- Failed Solenoid: In electronic systems (EUI and Common Rail), the electric coil that opens the injector can fail. This causes the injector to stop working completely. The result is a “dead” cylinder, which makes the engine misfire and shake violently.

- High-Pressure Pump Failure: This is the most expensive failure. It is almost always caused by fuel contamination (dirt) or fuel starvation (running out of fuel). When the pump fails, it often sends tiny metal particles through the entire system, destroying all the injectors at once.

The Most Important Rule: Keep Your Fuel Clean!

You can prevent almost all of these expensive problems with one simple rule: keep your fuel perfectly clean. The tiniest speck of dirt that you cannot even see is like a giant boulder inside a precision injector. Water is even worse, as it causes rust and destroys the lubricating film that protects the pump.

Always buy high-quality fuel from a trusted source. Never put fuel in from a dirty can. Most importantly, change your fuel filters according to your machine’s service schedule. A fuel filter is very cheap; a set of new injectors is not.

Conclusion

Diesel fuel injector systems are the high-tech heart of the modern diesel engine. They are responsible for turning liquid fuel into a fine, flammable mist, which is the key to the engine’s power, efficiency, and clean operation.

From the old mechanical pumps to the new common rail systems, the goal has always been more precise control. Understanding how these systems work shows why it is so important to protect them. Clean fuel and regular maintenance are the best ways to keep your engine reliable and strong for years to come.

What is the biggest fuel system problem you have ever had to fix?

At Merdeka Precision, we are experts in the complex world of diesel fuel. Our professional diesel injection services are a core part of our complete engine reconditioning solutions. We provide these high-quality services to a wide range of industries. If your diesel engine is showing signs of trouble, contact us to learn how we can help.