Imagine your engine as a team of rowers. They all push at different times, but they must turn a single pole to move the boat. That pole is your crankshaft, and it takes every bit of force your engine creates.

If this part fails, your heavy machinery stops instantly. A worn crankshaft can turn a busy workday into a quiet, expensive disaster. Understanding the warning signs can help you stop a small problem from becoming a total loss.

The Role of Your Crankshaft

Your engine turns fire into movement. The pistons move up and down, but your wheels need to turn in circles. The crankshaft makes this change happen by acting like a bicycle’s pedals and crank.

It handles incredible stress every second it spins. Engineers calculate the force on a journal using the formula for pressure:

where F is the force from combustion and A is the area of the bearing. If the surface of the metal wears down, this balance breaks.

Identifying the Symptoms of a Worn Crankshaft

You do not need to take your engine apart to know something is wrong. Your machine will tell you a worn crankshaft through sounds, shakes, and smells. Watch for these seven signs to catch a problem early.

1. The Deep Knocking Sound

The most famous sign of a worn crankshaft is a heavy knocking sound. This noise often comes from the bottom of the engine block. It sounds like someone is hitting a heavy piece of metal with a hammer.

This happens because the gap between the crankshaft and its bearings has grown too large. The metal parts actually hit each other instead of gliding on a thin film of oil. This is often called “rod knock” and requires immediate piston rod services to fix.

2. A Drop in Oil Pressure

Oil pressure is the lifeblood of your machine. The crankshaft needs a constant flow of oil to stay cool and slippery. If the journals wear down, the oil can escape too easily from the sides.

When this happens, your oil pressure gauge will show a lower number than usual. You might see the warning light flicker when the engine is hot. Low pressure means the metal is rubbing, which leads to even more wear.

3. Strange Shaking or Vibration

A healthy engine should run smoothly. The crankshaft is balanced with weights to stop it from shaking as it spins at high speeds. If the metal wears unevenly, this balance disappears.

You will feel a vibration that gets worse as you speed up the engine. This is called torsional vibration. If you feel your machine shaking in a new way, check the crankshaft before it snaps in two.

4. Metal Shavings in the Oil

Your oil filter works hard to keep your engine clean. During your next oil change, look closely at the old oil in the pan. If you see shiny flakes that look like glitter, you have a problem.

These flakes are tiny pieces of your crankshaft or its bearings. They have been ground off by friction and are now moving through your entire engine. This grit can damage your cylinder block services and other vital parts.

5. Engine Misfires or Hesitation

The crankshaft tells the rest of the engine when to move. It is connected to the camshaft services by a belt or chain. If the crankshaft is worn or bent, the timing of the engine will be slightly off.

You might notice the engine stumbles when you try to move a heavy load. It may also have trouble starting in the morning. Even a tiny change in timing can cause a big loss in power.

6. Visible Scratches or Cracks

Sometimes you can see the damage if you look through an inspection port. A worn crankshaft will have deep lines or grooves on its polished surfaces. You might also see tiny lines that look like spider webs.

These lines are stress cracks. Under high pressure, these cracks will grow until the part breaks completely. If you see any marks on the journals, you need professional crankshaft services right away.

7. Overheating Issues

Friction creates heat. When a crankshaft is worn, it creates much more friction than a smooth, new part. This extra heat can overwhelm your cooling system.

You might notice that your engine temperature stays high even when you are not working hard. If your coolant is fine but the engine is still hot, look for internal friction. This heat can warp your cylinder head services and lead to a very high repair bill.

Why Do Crankshafts Wear Down?

Crankshafts are designed to last for a long time. However, certain conditions can cause crankshaft failures to occur much faster than planned. Knowing these causes helps you protect your equipment.

- Lack of oil is the most common reason for a worn crankshaft.

- Using the wrong type of oil can fail to protect the metal.

- Dirty oil acts like sandpaper and grinds the metal away.

- Overloading the machine puts too much pressure on the bearings.

- Engine overheating can thin the oil until it stops working.

What to Do When You Find Damage

If you find any of these symptoms, do not keep working. Running a machine with a bad crankshaft is like walking on a broken leg. You will only make the damage much worse.

- Stop the engine immediately to prevent a total break.

- Drain the oil and check for metal pieces.

- Call an expert to measure the “runout” of the shaft.

- Look into engine reconditioning to save the part.

- Replace the bearings with the correct size after machining.

The Science of a Smooth Spin

A crankshaft must be perfectly straight. We measure this using a tool called a dial indicator to check for “runout.” If the shaft is bent even by the width of a human hair, it will fail.

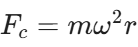

The speed of the spin also matters. The centrifugal force can be calculated as:

As the speed Omega increases, the force Fc grows very fast. This is why a small wobble at a low speed becomes a violent shake at a high speed.

Saving Your Engine with Reconditioning

You do not always have to buy a brand-new crankshaft. Most worn parts can be fixed by a professional machine shop. This saves you a lot of money compared to buying a new unit.

Machinists can grind the journals to a smaller size and use thicker bearings. This makes the surface smooth and round again. This is a standard part of precision component manufacturing for heavy engines.

Final Thoughts on Maintenance

Your crankshaft is the most hard-working part of your machinery. It turns raw force into the motion that gets your work done every day. By watching for these seven symptoms, you can protect your investment.

Check your oil often and listen to the sounds your engine makes. Small changes in noise or vibration are usually the first clues of a problem. Catching a worn crankshaft early is the best way to keep your business moving.

Do you have a machine that makes a strange sound you cannot explain?

At Merdeka Precision, we know how important your equipment is to your success. We use the latest technology to fix complex engine parts and keep your business running. Our team provides high-quality precision engineering Tangerang to ensure your crankshafts and engines stay in perfect shape. If you need help with your machinery, we are ready to assist you with our expert repair and manufacturing solutions. Would you like us to review your engine’s maintenance schedule?